Guanheng is specialized in steel structure engineering since 1987.

English

English

Guanheng is specialized in steel structure engineering since 1987.

English

English

Description:

FRP antenna cover is widely used in all kinds of communication facilities. This product is made of fiberglass fiber composite material. It has beautiful appearance, light weight, convenient processing, transportation and installation, good electrical insulation, strong wave permeability, UV protection and shock resistance. In the high temperature, low cold and other adverse environment it is still in good performance. In the communications industry is increasingly developed today. As the outermost protective cover of radar antenna, FRP exerts its unique advantages such as electrical performance and light weight, which greatly improves the excellent physical properties of the antenna. It is often used in plate antenna, tube omnidirectional antenna, etc. We can make the sample according to the customer’s drawings in various styles, this product’s advantages is: custom design style, suitable for all kinds of environment, more less difficulty of location, antenna is completely hidden.

| Origin | China | Minimum Order | 1 set | |

| Payment term | L/C, T/T | Shipment term | FOB, C&F, CIF | |

| Height | 1to 6 meters | |||

| Material | FRP fiber composites | |||

| Tolerance | According to your request | |||

| Surface test | FRP material , Good anti-acid and alkali protection, High and low temperature performance stability, Strong wind resistance, sturdy structure. | |||

| Connection Mode | Screw and steel connection | |||

| Standard | ISO 9001:2008, ISO14001:2005, OHSAS18001 | |||

| Per Section Length | Below 6 meters | |||

| Wind Pressure | 0.35-1.00 KN/m2 | |||

| Production Procedure | Making mould →coating mould discharging agent →Hand paste mouding→Resin glue preparation →Reinforcement material preparation→welding →knockout → reprocessing→ check→product→flame plating→finished product→shipment | |||

| Packing | Pack in plastic paper or under customer's request | |||

| Shipment date | Quantity | Delivery day | ||

| 100 sets | 30 days | |||

Glass fiber reinforced plastic antenna cover is for any environment and occasion, this cover is for hanging wall design, it is model on the wall so that the antenna and line can be hidden.

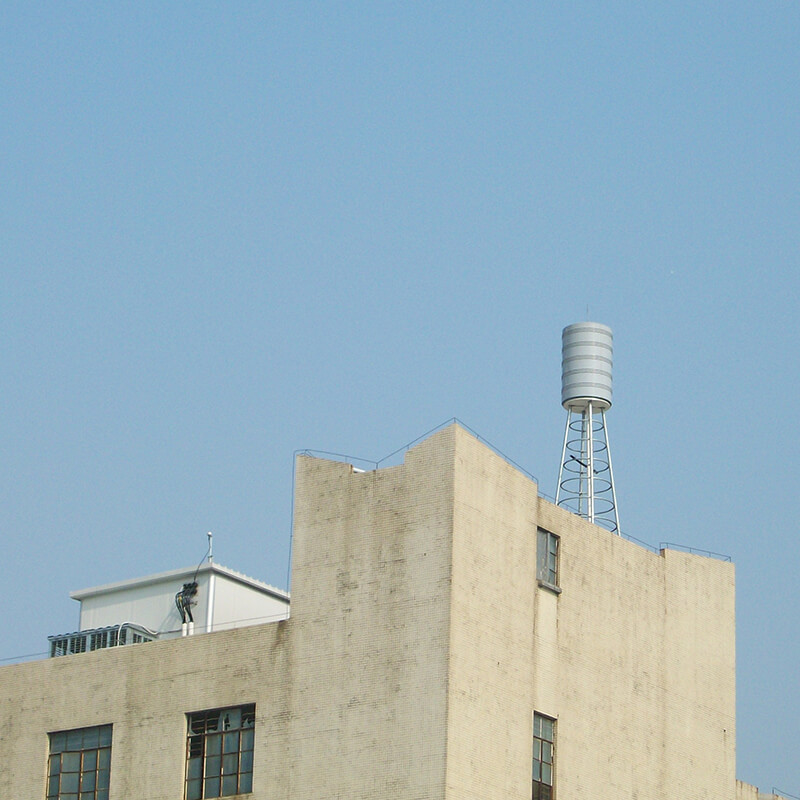

In this case, the solar water heater is used to beautify the solar antenna base station and imitate the roof of the apartment building. This beautified antenna cover is easy to install and easy to handle. The antenna is installed in the inside of the solar water heater-shaped glass fiber reinforced plastic (FRP). The surface color of the hidden body is similar to that of the solar water heater,it shows a good impression of cleanness and neatness and harmony with the site environment.

1. All the original materials and finished products should be 100% checking.

2. We already obtain the ISO 9001:2008, ISO14001:2005 and OHSAS18001 quality and safety certificate.

Split Charging → Partial Packing → Part Remark → Loading → Shipment

Copyright © 2018 Foshan nanhai guanheng steel structure co. LTD. | All Rights Reserved